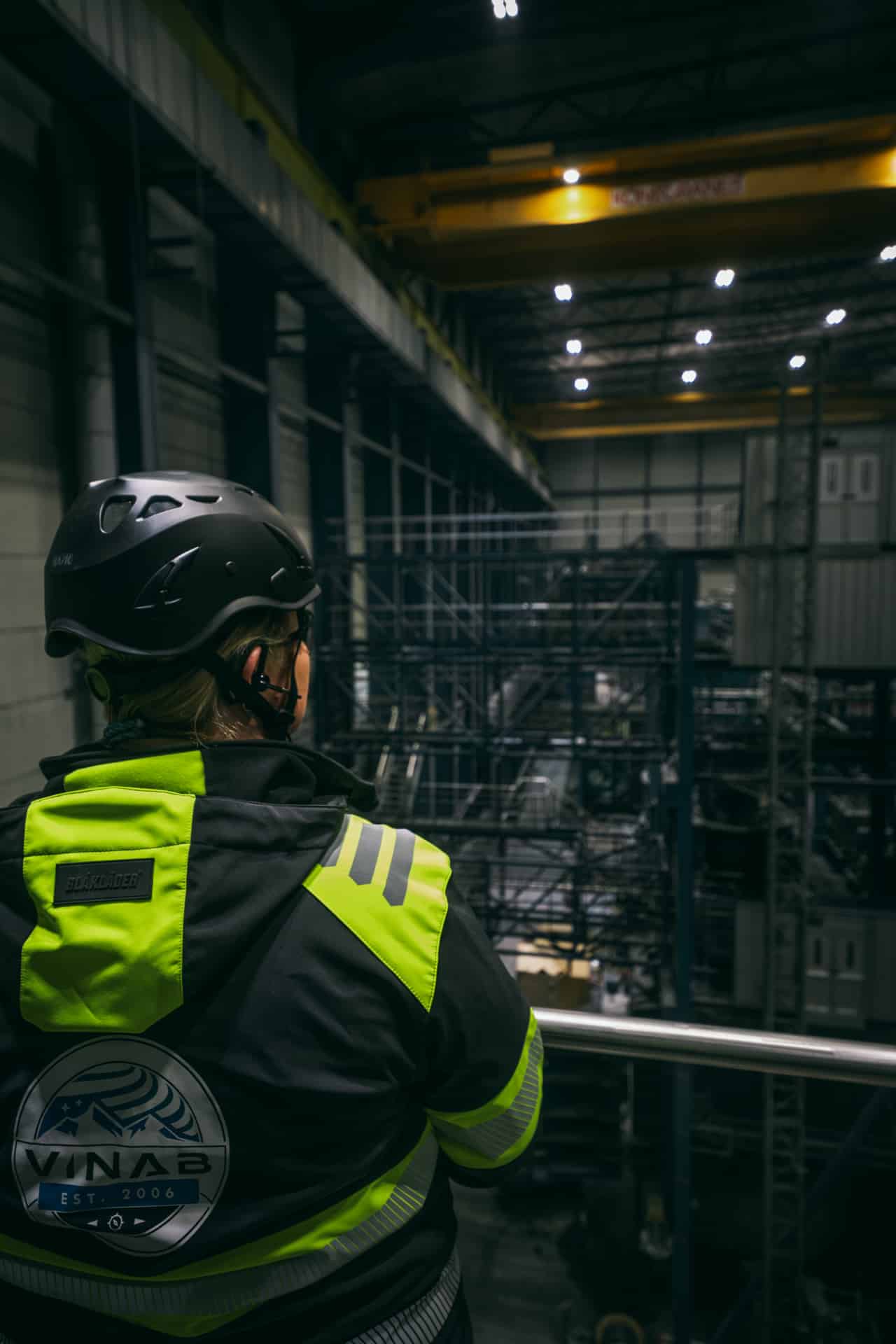

In a milestone for the mining and construction industry in Northern Sweden, Kaunis Iron, in close cooperation with VINAB, is taking an important step forward by expanding the flotation plant for more efficient ore enrichment. This development marks not only a technical success but also a deepened cooperation between the two companies.

Project overview:

VINAB has been awarded responsibility for several piping contracts with an order value in excess of SEK 100 million. These projects reflect our commitment to delivering expertise and innovative solutions:

Reagent building piping contract:

Includes the fabrication and assembly of stainless steel welded process piping, pumps, valves, and a complete heating system for the reagent building.

Flotation plant piping contract:

The project involves the assembly and fabrication of stainless steel welded process pipes up to DN800 size, with some lines equipped with the flexible Victaulic system.

Outer waste pipeline piping contract:

Includes the assembly and welding of PE pipes, extending from the concentrator to the landfill, in dimensions up to DN350-450.

Rain tanks:

The project includes the manufacture and assembly of approximately 20 stainless steel tanks for the reagent building, with capacities up to 100 m³, all manufactured in VINAB’s workshops in Norrbotten.

“The challenge with the projects has been the tough schedule, during the most demanding period we have been about 60 people. We have seen all projects as a pleasant challenge and have never had any problems to land these due to our enormously skilled pipe fitters, welders and other employees”

– Says Jörgen Nilsson, Pipe Manager at VINAB.

We are grateful for the trust placed in us by Kaunis Iron and proud to have been part of these projects. Our cooperation underlines not only the technical capabilities of our companies but also our common vision for the sustainable development of the region.